At Williams Metalfinishing, where we’ve earned our reputation as metal polishing experts since 1975. On-site, we have 24 hand-polishing and buffing stations manned by extremely skilled operators. In addition, there are centerless polishing cells, bar and tube polishers, linear pipe polishing cells, automated belt sanders and buffing cells. Together, our employees, leading-edge equipment and modern facility allow us to take on products of all shapes, sizes and weights in a wide range of metals.

To meet our customers’ requirements, we provide a selection of finishes, from #4 architectural to #8 mirror and to any specific RA finish. Our repeat customers include companies in the aerospace, general fabrication, auto/truck/transportation, dairy and casino sectors. We work with our customers in a number of industries and we are ISO 9001:2015 certified to ensure consistent superior quality. In addition, we also have the ability to comply with multiple industry standards as shown in the table below.

We regularly share our expertise and experience with customers through our part development, engineering and consulting services. Depending on the circumstances, we can suggest process improvements that can boost efficiency, contain costs and further enhance quality.

For more information on our custom metal polishing services, see the table below and contact us directly.

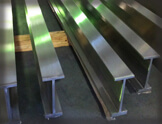

Bar, Tube, Angle, Rod, I-Beam, U-Channel Metal Polishing Capabilities

| Processes |

|

| Equipment Used |

|

| Part Length | No limitation imposed by the equipment or facility |

| Part Width | No limitation imposed by the equipment or facility |

| Part Height | No limitation imposed by the equipment or facility |

| Part Weight | No practical limit |

| Finishes Available |

|

| Substrates |

|

| Other Features | Protective packaging for shipment |

| Customer Services |

|

| Intended Application |

|

| Industry Focus |

|

| Industry Standards |

|