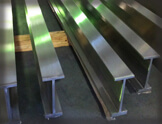

For over 40 years, Williams Metalfinishing has performed high quality metal polishing services with a special focus on highly complex, custom projects. Our processes, which include automated, mechanical and hand metal polishing leverage the expertise of our skilled operators as well as our state-of-the-art equipment.

At Williams Metalfinishing, we can take on parts up to 35 ft. long and virtually any width, height and weight. We’re adept at polishing myriad shapes, from fabrications, weldments, castings, forgings, stampings, spinnings and machined parts in substrates such as brass steel, aluminum, stainless steel, titanium and beryllium. To meet the needs of our clients, we offer multiple finishes types, including #4 architectural, #4 dairy (sanitary, pharmaceutical) and #7 and #8 mirror as well as any specific RA finish. To maintain the integrity of these finishes once we’ve completed our polishing processes, we carefully wrap parts in protective packaging for shipment.

In alignment with our strict ISO 9001:2015 requirements, we always provide superior quality and on-time delivery. We also comply with multiple industry standards, including Mil-Spec and NADCAP, in accordance with the relevant industry regulations. We also conduct regular quality audits because we embrace a philosophy of continuous improvement.

As part of our commitment to consistently outstanding quality, we also offer numerous added-value services. Our ability to provide part development, engineering and consulting expertise allows us to recommend important process improvements. To learn more about our quality metal polishing services, see the table below and contact us directly.

Complex Shaped Large & Small Metal Polishing Capabilities:

| Processes |

|

| Equipment Utilized |

|

| Part Length | Up to 35 ft. |

| Part Width | No Limitation Imposed by The Equipment or Facility |

| Part Height | No Limitation Imposed by The Equipment or Facility |

| Part Weight | No Practical Limit |

| Shapes |

|

| Finishes Available |

|

| Substrates |

|

| Other Features | Protective Packaging for Shipment |

| Customer Services |

|

| Intended Applications |

|

| Industries Served |

|

| Industry Standards Met |

|