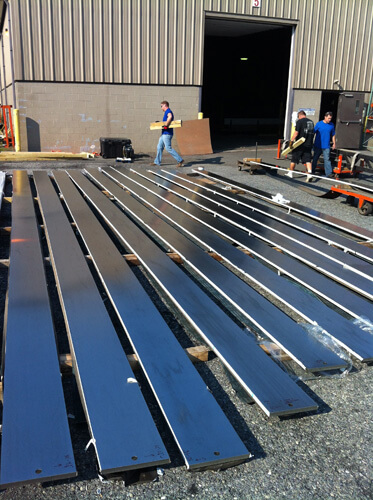

Williams Metalfinishing was approached by one of the top 5 technology companies in the world, who requested a very specialized stainless steel architectural polishing of beams for one of their retail stores. We were the only company capable of fulfilling this customer’s requirements. Used to support a thick tinted glass ceiling, these beams also contained the lighting and sprinkler systems.

To complete this polishing job, we made custom modifications to our polishing equipment. The beams were made from 304 stainless steel and measured 33′ long, 12″ wide, 1″ thick, and weighed 1,400 lbs. each. The finish required by the client was #6 pit-free brushed, which was very unique in such large pieces. Each beam was visually inspected for defects and a final quality inspection was performed. We completed 30 beams in 30 days and delivered the beams to the client’s site in California. To learn more about this polishing of a stainless steel support beam project, please see the table below or contact us.

Highlights of this Polishing of a Stainless Steel Support Beam Project

| Product Description | These polished beams are used to support a thick tinted glass ceiling and contain the lighting and sprinkler systems for a worldwide top 5 technology company. |

| Polishing Capabilities Applied/Processes | Primary:

|

| Equipment Used to Polish Part | Custom Modified Equipment to do the Polishing |

| Overall Part Dimensions |

|

| Material Used | 304 Stainless Steel |

| Material Finish | #6 Pit-Free Brushed |

| Additional Facts | Only company in the United States capable of doing this job. |

| In process testing/inspection performed | Visual & Quality Inspection |

| Industry for Use | Retail Store |

| Volume | 30 |

| Delivery/Turnaround Time | 30 Days |

| Delivery Location | California |

| Standards Met | Customer Specifications |

| Product Name | Support Beams |