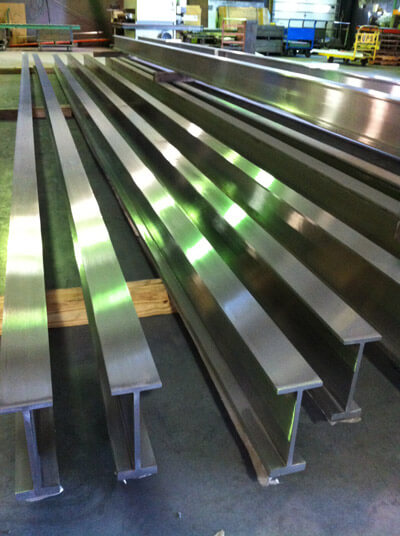

A food industry client was building a state-of-the-art research center and the building specifications required that the facility be constructed entirely of #4 polished stainless steel for sanitary purposes. They came to us knowing we had the expertise to polish I-beams to this dairy grade finish.

Being used as wall framing, these I-beams were made from 304 stainless steel. We were able to polish these beams to their final finish by custom modifying existing polishing equipment. We produced 42 beams. Each beam had dimensions of 30′ long, 23″ wide, 8″ high, and a weight of 650 lb. Beams were quality inspected and visually checked for imperfections. We completed this project in 8 weeks and met the customer specifications.

Williams Metalfinishing specializes in meeting the most demanding metal supply needs. The following table outlines this polishing of a stainless steel I-beam project. For more information, please feel free to contact us.

Highlights of this Stainless Steel I-Beam Polishing Project

| Product Description | These I-beams were used for the wall frame structure of a research center. |

| Polishing Capabilities Applied/Processes | Primary:

|

| Equipment Used to Manufacture Part | Custom Modified Equipment to do the Polishing |

| Overall Part Dimensions |

|

| Material Used | 304 Stainless Steel |

| Material Finish | #4 Dairy Grade |

| In process testing/inspection performed | Visual and Quality Inspection |

| Industry for Use | Food Research |

| Volume | 42 |

| Delivery/Turnaround Time | 8 Weeks |

| Delivery Location | Ithaca, New York |

| Standards Met | Customer Specifications |

| Product Name | I-beams |